Ferre / Sustainability / Circular process

From waste to yarn. A circular process.

After more than seven decades supplying recycled yarns to the fashion industry, circularity is in our DNA. Recycled raw material, with minimal chemicals, water and minimal CO2 emissions. Circular business models have always fueled our resource- and energy-efficient yarn manufacturing process and helped us minimize our impact.

Textile waste is our raw material

We use pre- and post-consumer textile waste as a source of raw material. By doing so, we prevent textile waste from going to landfill or incineration and are less dependent on virgin and finite raw materials.

Cotton Fiber Recycling

Recover™, our strategic partner in the sustainable supply chain, turns textile waste into new recycled cotton fiber, ensuring the best quality and maximum fiber length.

Developing low-impact blends

The Recover™ ColorBlend System blends Recover™ undyed recycled cotton fiber with other support fibers that have been low-impact dyed (recycled PET, recycled wool, recycled nylon, organic cotton, …), to create new fibers with accurate and unique colors with minimal water and chemicals.

The blends

The low-impact fibers blend is reproduced on an industrial scale and subsequently subjected to various intimate blending processes in the blending boxes until achieving the perfect combination of performance and color matching accuracy.

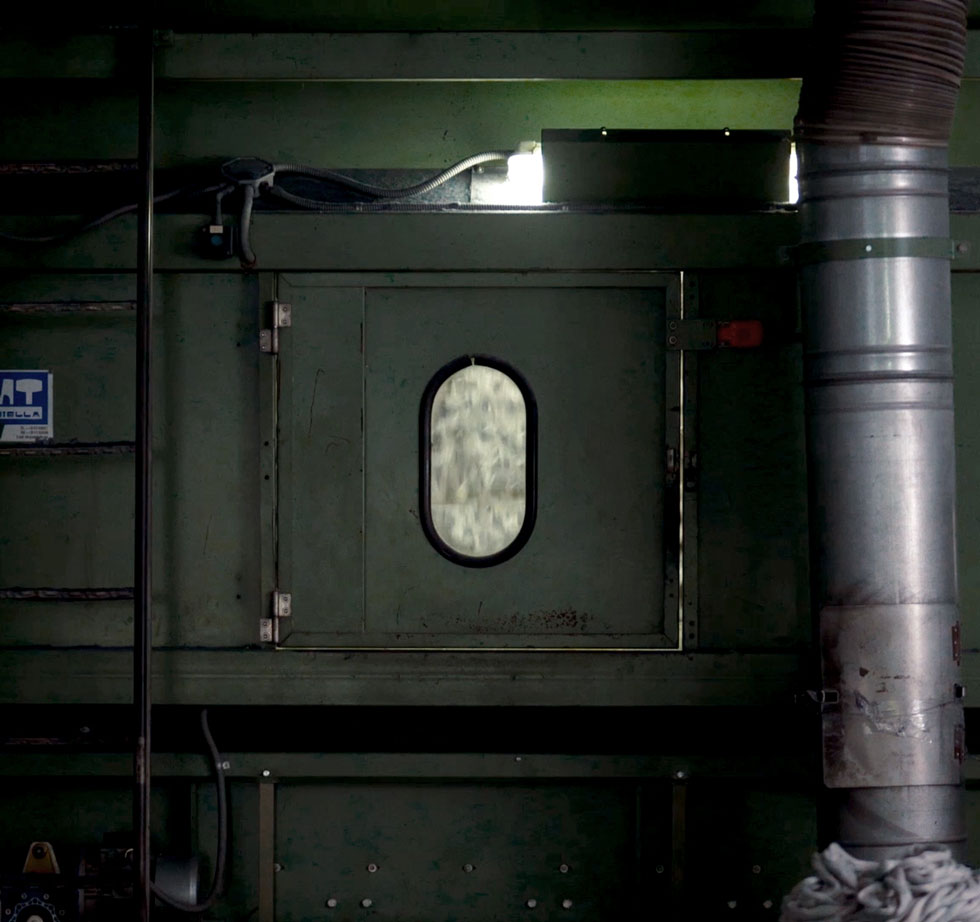

Spinning

The recycled fiber blends are spun into low-impact premium yarns for all types of fashion, accessory and home textile products, in a full spectrum of accurate and unique colors.